At Ingredia, the quality of our ingredients and customer satisfaction are primordial.

This is why we have our own pilot plant.

It allows us to recreate the industrial environment of a chocolate factory, enabling us to test our ingredients and closely simulate the real-life conditions faced by our clients.

In this video, our Chocolate Application Specialist, Wenqian SUN, will demonstrate our expertise in chocolate manufacturing processes.

Our expertise in the chocolate industry enables us to offer a specialized range of ingredients specifically tailored for this market under our product line, PROCHOC®.

Traditionally, most milk chocolates manufacturers use whole milk powder, which can sometimes present challenges.

However, at Ingredia, we provide a solution with our milk powder specially designed for chocolate and labelled as “Whole Milk Powder”: PROCHOC® S 26 +.

This spray-dried whole milk powder contains 75% free fat, offering several significant advantages:

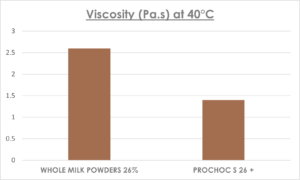

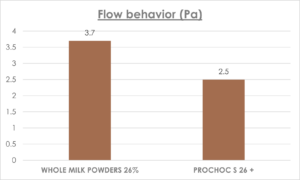

- Enhanced tempering properties: the higher free fat content in our product facilitates tempering process. This results in reduced viscosity during chocolate production and improves overall flow behavior (see graph below).

- Economies: by incorporating our product into your chocolate recipe, you can reduce the amount of cocoa butter required during the conching stage. This not only streamlines the manufacturing process but also provides cost savings without compromising the quality or texture of the final chocolate product.

These advantages underscore our commitment at Ingredia to providing innovative solutions that meet the specific needs of chocolatiers, ensuring optimal performance and economic viability in chocolate production.